Product Parameter

| Equipment name | electric calf feeding truck |

| Product model | ECT2 |

| Power category | Electric |

| Driving way | Hydraulic,double-disk double side driving |

| Power model | 12pieces 6v 200Ah maintenance-free |

| Drive type | ntelligent controller, 10KW motor |

| Rear axle | SL-D40 |

| Front axle | SL-D40 |

| Braking method | Oil brake |

| Gradeability | ≤8 |

| Wheel track | front and rear 1500mm |

| Tire model | Front 650-16 mine Rear 700-16 mine block |

| Overall dimension | Length 4550mm* width 1500mm* height 2000m |

| Milk tank dimension | Length 2000mm* width 1400mm* height 1150mm |

| Milk tank volume(m³) | 2 |

| Milk tank plate thickness | 3+2mm double-layer insulation stainless steel |

| Cleaning | High pressure cleaning |

Features

The electric system is powered by 12 pieces of 6V 200Ah maintenance-free batteries, equipped with an intelligent controller and a 10KW electric motor, providing efficient power output.

The truck is equipped with an SL-D40 rear axle and an SL-D40 front axle, using oil brakes for braking. It has good gradeability (≤8) to adapt to different terrains and road conditions.

The wheel track of the vehicle is 1500mm for both the front and rear, and it is equipped with special mine tires. The front tires are 650-16 mine tires, while the rear tires are 700-16 mine block tires, providing excellent traction and maneuverability.

The overall dimensions of the truck are length 4550mm * width 1500mm * height 2000mm, and the milk tank dimensions are length 2000mm * width 1400mm * height 1150mm. The milk tank has a volume of 2 cubic meters.

The milk tank is made of 3+2mm double-layer insulated stainless steel plates, offering excellent insulation performance. Additionally, the truck is equipped with a high-pressure cleaning system for easy cleaning and maintenance.

This independently developed electric calf feeding truck offers efficient and reliable performance, providing a convenient and sustainable solution for calf feeding. Its design takes into consideration factors such as driving stability, power output, traction, and cleanliness, thereby enhancing convenience and efficiency in milk production processes.

Frequently Asked Questions (FAQ)

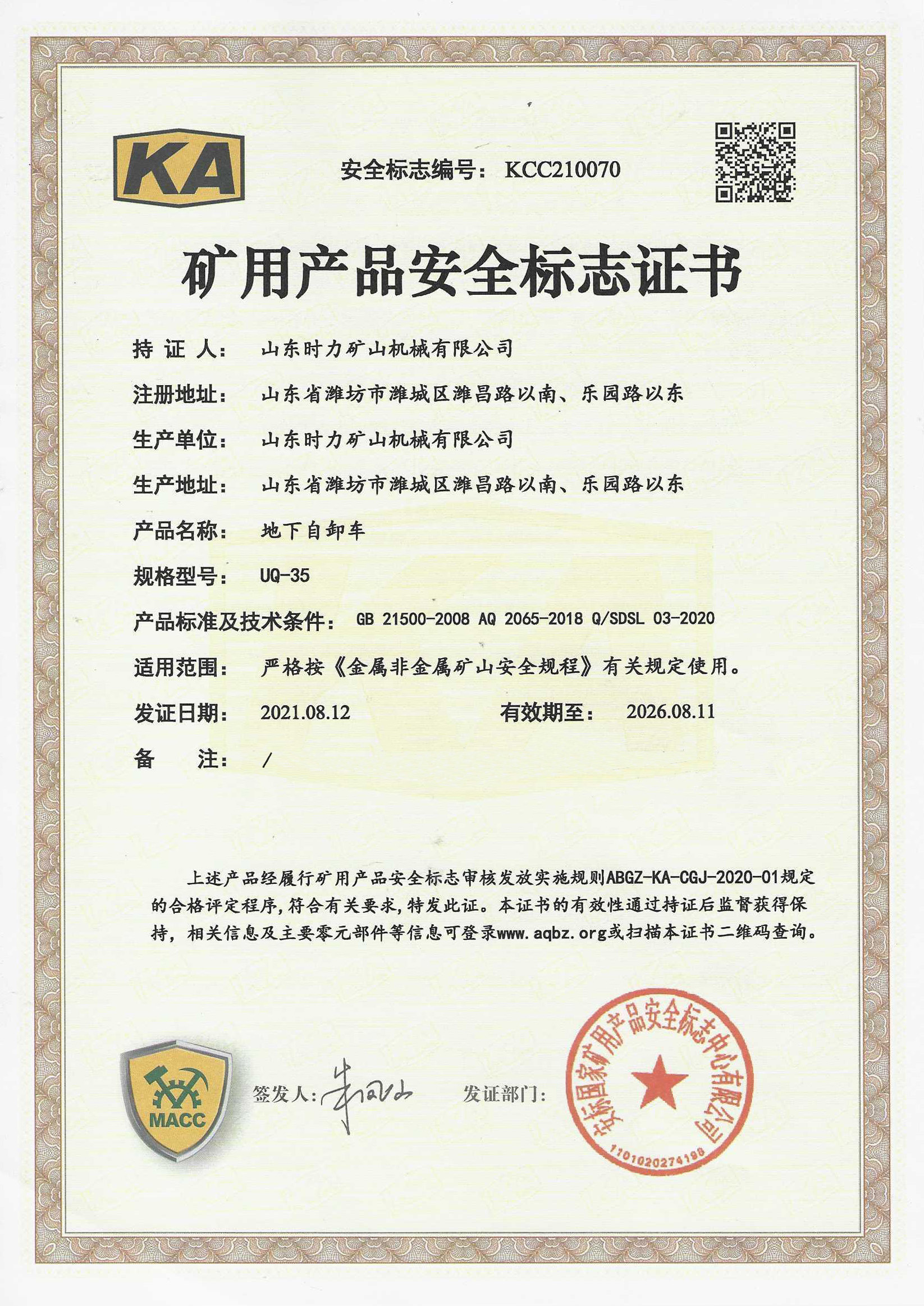

1. Does the vehicle meet safety standards?

Yes, our mining dump trucks meet international safety standards and have undergone a number of rigorous safety tests and certifications.

2. Can I customize the configuration?

Yes, we can customize the configuration according to customer needs to meet the needs of different work scenarios.

3. Which materials are used in body building?

We use high-strength wear-resistant materials to build our bodies, ensuring good durability in harsh working environments.

4. What are the areas covered by after-sales service?

Our extensive after-sales service coverage allows us to support and service customers around the world.

After-Sales Service

We offer a comprehensive after-sales service, including:

1. Give customers comprehensive product training and operation guidance to ensure that customers can correctly use and maintain the dump truck.

2. Provide rapid response and problem solving technical support team to ensure that customers are not troubled in the process of use.

3. Provide original spare parts and maintenance services to ensure that the vehicle can maintain good working condition at any time.

4. Regular maintenance services to extend the life of the vehicle and ensure that its performance is always maintained at its best.